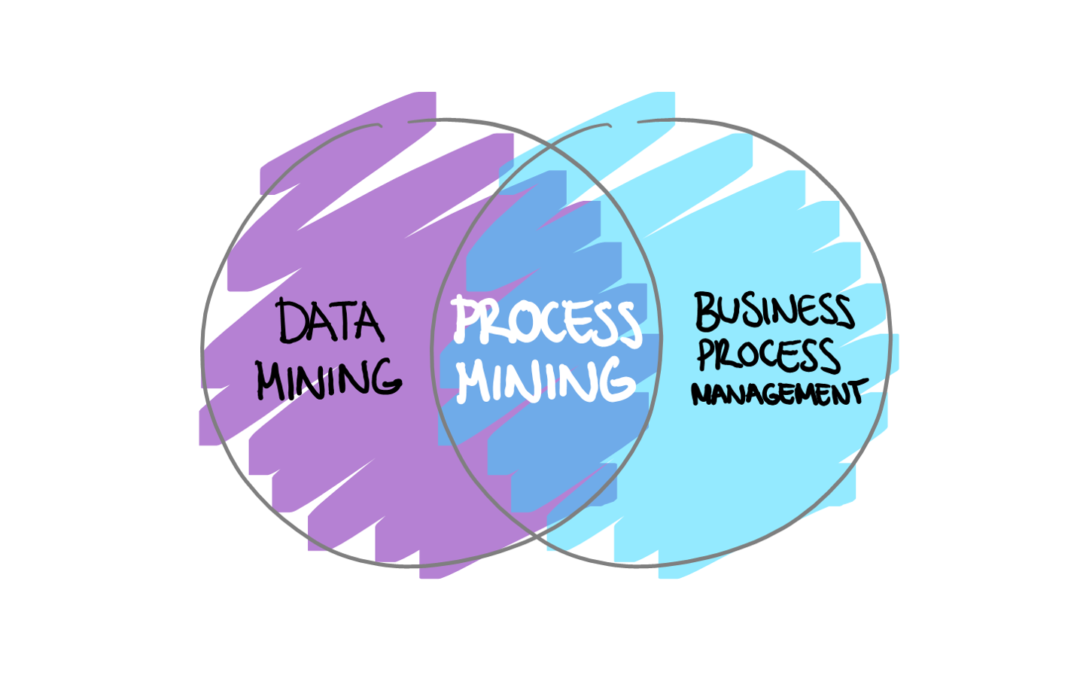

Process mining combines computational intelligence, data mining, process modelling and process analysis to discover, monitor and improve real processes. Event logs recorded in enterprise information systems form the basis for all process mining techniques to extract relevant knowledge regarding process activities and instances as well as additional information about resources that initiate an activity, timestamps and any other process-related data elements that have been recorded.

The Process Mining Manifesto defines three broad types of process mining techniques:

- Process discovery: Discovery techniques focus on extracting process models from event logs without requiring any additional information about the activity.

- Process conformance: Where discovery creates process models from event log data, conformance techniques are used to monitor process deviations by comparing event log data against an existing process model. Conformance techniques can also be used on-the-fly to provide real-time warnings, predictions, and recommendations based on comparing the existing process model with event data related to running process instances.

- Process enhancement: In this technique, the combination of an existing process model and actual process log data is leveraged not just to establish conformance but to actually reengineer, extend and update the existing process model.

Process mining can also be applied for variant analysis of multiple versions of the same business process. For instance, businesses can use this approach for a detailed analysis of the differences in the workflows underlying cases with a positive outcome and those with an unfavorable outcome to identify opportunities for optimization.

Process Mining in ERP Migration

A spate of high-profile ERP project failures has only served to emphasize the importance of extensive planning and risk management when it comes to ERP migration. Process mining technologies play a critical role in helping businesses identify and manage the execution and disruption risks of these complex transformation programs.

Process mining allows businesses to create a process efficiency baseline by using data from the existing system to identify optimal processes and best practices as well as highlight inefficiencies and limitations. These data-driven insights can help build a robust business case on the shortcomings that have to be addressed and on the new functionalities/capabilities that are required for ensuring optimal business outcomes. This baseline also serves as an objective benchmark against which to measure the performance of the new ERP system.

With process mining, companies can automatically discover as-is processes and gain real-time end-to-end visibility into all enterprise workflows together with detailed information about underlying workflows, deviations and resources involved. Importantly, the scope of discovery extends beyond a company’s ERP systems to include all critical processes across the entire enterprise stakeholder ecosystem. Advanced capabilities like business rule mining can automatically identify the logic that determines process behavior thereby making it easier to refine rules and ensure that they are perfectly aligned with business strategy.

Modern process mining solutions also enable businesses to model and simulate future-state processes in order to understand how even localized changes will impact system-wide performance and business outcomes. Organizations can experiment with thousands of what-if simulations to iterate towards an optimal should-be process model that can serve as the template for execution. The capability to simulate complex scenarios prior to the execution and to resolve any adverse outcomes significantly reduces the risk of post-migration disruption.

In the post-migration stage, process mining technologies can be used to monitor the performance of as-is processes in the new ERP system and compare them to should-be benchmarks to make incremental adjustments and maximize performance.

The process conformance functionality of process mining solutions can also be leveraged to train employees on the new system. By comparing actual process activities with ideal process activities, businesses can quickly identify the cause, frequency and cost of any deviations and address them in a timely and cost-effective manner.